< Previous | Contents | Next >

Section 6 Welding Consumables

601. General

1. Application

In application to 601. 1 (3) of the Rules, the term "the discretion of the Society" means the ac- ceptance in accordance with Pt 1, Ch 1, 104. or 105. of the Guidance.

602. Electrodes for manual arc welding for normal strength steels, higher strength steels and steels for low temperature service.

1. Application

In application to 602. 1 (2) of the Rules, the term "the discretion of the Society" means the ac- ceptance in accordance with Pt 1, Ch 1, 104. or 105. of the Guidance.

2. General provisions for tests

Hot cracking test specified in 602. 3 (1) of the Rules is to be done as follows :

![]()

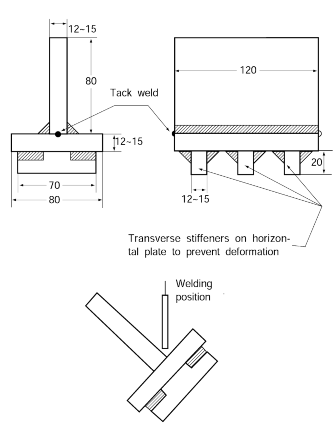

(1) Test assemblies are to be T-joint shape as shown in Fig 2.2.9 of the Guidance. The bottom of the vertical plate is to grind straight, and adhere closely on the surface of horizontal plate. All surface rough( ) on the plate is to be removed before welding. The tack welds in prepara- tion for the fillet welds is to make at the both ends of the plate. Three transverse stiffeners are to reinforce the horizontal plate to prevent welding deformation.

Fig 2.2.9 Hot Cracking Test Assemblies (Units : mm)

(2) The number of test assembly is to be prepared for every each diameter of electrodes.

(4 mm, 5 mm or 6 mm)

![]()

44 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

(3) The fillet welding is to be carried out in the downhand position in one pass on each side and the welding current used is to be the maximum of the range recommended by the manufacturer for the size of electrode used.

(4) The second fillet weld is to be started immediately after the completion of the first fillet weld from the end of the test specimen at which the first fillet weld was finished. Both fillet welds

are to be executed at a constant speed and without weaving.

(5) Length of fused electrode in hot cracking test are to be as shown Guidance according to the diameter of electrodes.

(6) After welding, the slag is to be removed from the fillet welds and after

Table 2.2.11 of the

complete cooling, they

are to be examined for cracks by a magnifying glass or by using penetrant fluids.

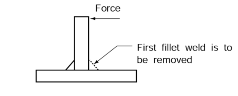

(7) The first fillet weld is then to be removed by machining or gouging and the second weld bro- ken by closing the two plates together, subjecting the root of the weld to tension (See Fig

2.2.10 of the Guidance). The weld is then to be examined for evidence of hot cracking.

Table 2.2.11 Length of Fused Electrode in Hot Cracking Test (Units : mm)

Diameter of electrode | Length of fused electrode | |

1st fillet | 2nd fillet | |

4 | Approx. 200 | Approx. 150 |

5 | Approx. 150 | Approx. 100 |

6 | Approx. 100 | Approx. 75 |

Fig 2.2.10 Hot Cracking Test

(8) There is to be no cracking in the fillet welds either superficial or internal except crater crack.

3. Fillet weld test

In application to 602. 7 (3) of the Rules, the term "those deemed appropriate by the Society" means the acceptance in accordance with Pt 1, Ch 1, 104. or 105. of the Guidance.

606. One side welding and steels for low

1. Application

In application to 606.

consumables for normal strength steels, higher strength steels temperature service.

1 (2), (3) of the Rules, the term "deemed appropriate by the Society" means

the acceptance in accordance with Pt 1, Ch 1, 104. or 105. of the Guidance.

607. Welding consumables for stainless steels

1. Welding consumables for duplex stainless steels

In application to consumables used

607. 1 (2) of the Rules, the approval tests and annual inspections for welding for duplex stainless steels(hereinafter referred to as "welding consumables") are to

comply with the followings:

(1) General

Approval test items, test methods and acceptance criteria not specified in this Instruction are to be in accordance with Ch 2, Section 2 607. of the Rules.

(2) Grades and marks

(a) Welding consumables are classified as specified in Table 2.2.12.

Table 2.2.12 Grades and Marks of Welding Consumables

Electrode for manual arc welding | Material for TIG and MIG welding | Flux cored wire semi-automatic welding | Consumables for submerged welding |

RD 31803 | RY 31803 | RW 31803 | RU 31803 |

RD 32750 | RY 32750 | RW 32750 | RU 32750 |

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 45

![]()

(b) Grades and marks not specified in the preceding (a) are to be in accordance with Pt 2, Ch 2, 607. 2 of the Rules.

(3) General provisions for tests

(a) General provisions for tests are to be in accordance with Pt 2, Ch 2, 607. 3 of the Rules.

(b) Steel plates to be used in preparation of test assemblies are to be as given in Table 2.2.13

according to the grades of welding consumables.

Table 2.2.13 Grades of Steel for Test Assembly

Grade of welding consumables | Grade of steel for test assembly(1) |

RD 31803, RY 31803, RW 31803, RU 31803 | S 31803 |

RD 32750, RY 32750, RW 32750, RU 32750 | S 32750 |

NOTE: (1) Notwithstanding the requirements in this table, mild steel or higher strength steel may be used for deposited metal test assembly. In this case, test assemblies are to be appropri- ately buttered. | |

(4) Deposited metal test

(a) The chemical composition of the deposited weld metal shall be determined by the manu- facturer and reported the results of the analysis to the Society. The report is also to include

the main alloy elements. The results of the analysis shall not exceed the limit values speci- fied in the standards or by the manufacturer, the narrower tolerances being applicable in each case.

(b)

(c)

The tensile strength, yield point and elongation of each test specimen shall meet the speci- fied minimum value of the base material.

Deposited metal impact tests

(i) One set of three impact test specimens, from each test assembly, are to be machined to

dimensions charphy V-notch impact test specimens as shown in Table

The test specimen is to be cut with its longitudinal axis transverse to

welding, and the test specimen is to coincide with the mid-thickness of in Fig 2.2.19 of Rules.

(ii) The notch is to be positioned in the centre of weld and is to be cut in specimens perpendicular to the surface of plate.

(iii) 27J at -20°C is to be satisfied.

2.1.3 of Rules. the direction of

the plate shown

the face of test

(iv) When the absorbed energy of two or more test specimens among a set of test speci-

mens is less in value than the specified average absorbed energy or when the absorbed energy of a single test specimen is less in value than 70 % of the specified average ab- sorbed energy, the test is considered to have failed.

(5) Butt weld test

(a) The tensile strength, yield point and elongation of each test specimen shall meet the speci- fied minimum value of the base material.

(b) Butt weld bend tests are to be in accordance with Pt 2, Ch 2, 607. 3 of the Rules.

(c) Butt weld Impact test

(i) Kinds, numbers and selection method of the butt weld impact test specimens being tak- en from each test assembly are to comply with the requirements specified in 602. 5

(4), 603. 5 (4) or 604. 5 (4) of Rules according to the grade of the welding consumables.

(ii) 27J at -20°C is to be satisfied.

(iii) When the absorbed energy of two or more test specimens among a set of test speci- mens is less in value than the specified average absorbed energy or when the absorbed energy of a single test specimen is less in value than 70 % of the specified average ab- sorbed energy, the test is considered to have failed.

(6) Corrosion resistance test

(a) The corrosion resistance test of downhand specimen for butt weld test shall be carry out in

accordance with ASTM G48 Method A. The test temperature shall be 20°C and the ex- posure time shall be minimum 24h.

![]()

46 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

(b) Acceptance Criteria

(i) There shall be no pitting at 20 X magnification.

(ii) The weight loss shall be less than 20 mg.

(7) Micro structure test

The ferrite content in the weld metal shall be determined in accordance with ASTM E 562 and shall be in the range of 25% to 70%.

(8) Annual inspections

Annual inspections are to be in accordance with Pt 2, Ch 2, 607. 6 of the Rules.

2. General provisions for tests

In application to 607. 3 (1) of the Rules, the term "deemed necessary by the Society" means the acceptance in accordance with Pt 1, Ch 1, 104. or 105. of the Guidance. ![]()

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 47

![]()